The topic of laser electro-optical conversion efficiency has always attracted much attention, and some people even made a big fuss about it. So, let’s talk about this topic today:

1 What is the electro-optical conversion efficiency?

2 What are the difficulties in improving the efficiency of electro-optical conversion?

3 What is the electro-optical conversion efficiency of Raycus fiber lasers?

What is electro-optical conversion efficiency

The electro-optical conversion efficiency is an important indicator to measure the performance of a laser. In a nutshell, it refers to the energy conversion efficiency of converting electrical energy into laser light.

This indicator is directly related to production costs. Therefore, laser manufacturers at home and abroad are striving to make breakthroughs in technology to improve the electro-optical conversion efficiency of lasers.

What are the difficulties in improving the efficiency of electro-optical conversion?

From a technical point of view, 220V/380V is converted into various levels of voltage to drive the pump source after passing through the laser power supply (drive) system. The pump source converts electrical energy into pump light, and the pump light is converted into laser output after passing through the gain fiber and the fiber resonator.

There is a certain amount of energy loss in the above three conversion processes, and most of the lost energy is converted into heat. The increase of heat will cause the temperature of the laser to rise, and too high temperature will cause the laser output power to be unstable. Therefore, it is necessary to cool the laser through an external device, which will incur certain additional costs.

Higher electro-optical conversion efficiency means less heat generation. The pump source with high electro-optical conversion efficiency and the ytterbium-doped fiber with high optical conversion efficiency can reduce heat generation, thereby reducing the heat dissipation cost of the system. At the same time, it can also effectively improve the reliability of the device and achieve higher power and more stable laser output. Therefore, if you want to achieve higher electro-optical conversion efficiency, you must first increase the conversion efficiency of the pump source and the Ytterbium-doped fiber.

The self-developed 915nm pump source used by Raycus new generation laser has a rated output power of 10~400W, an electro-optical conversion efficiency greater than 50%, and an average electro-optical conversion efficiency of 55%-57%. The new generation of high-power ytterbium-doped fiber has more uniform doping, a 50% increase in absorption coefficient, and a 40% increase in withstand power. At the same time, using a new power drive system, the optical conversion efficiency of the whole machine can be increased by at least 5%.

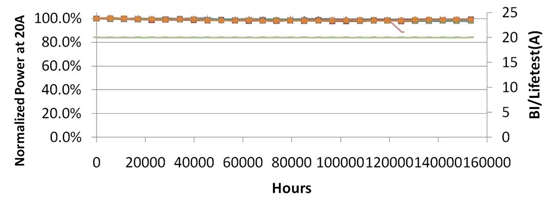

In addition, the electro-optical conversion efficiency has a great relationship with the temperature of the device. Raycus has conducted a long-term high-temperature aging test for the 915nm pump module. The test time is more than 8,000 hours, and the accelerated aging is 33.8 times faster, which is equivalent to 270,400 hours. During the test, the pump source can maintain a stable power output. Nearly harsh testing is to provide customers with laser products with higher stability and reliability.

Reliability test of 915nm pump module

What is the electro-optical conversion efficiency of Raycus lasers?

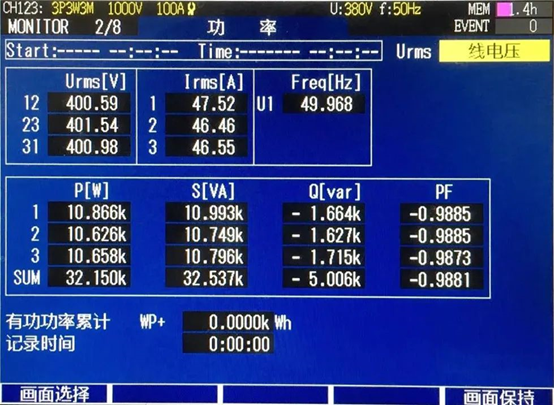

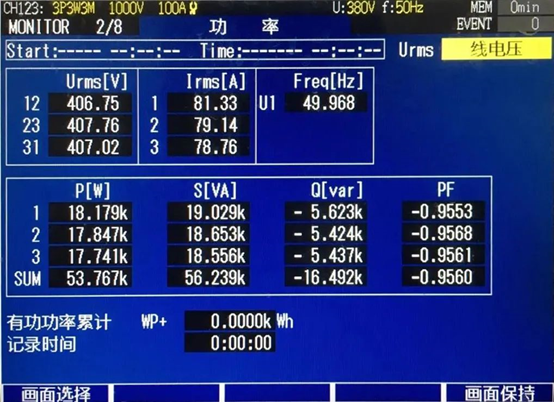

We speak with measured data! A 12000W and 20000W continuous fiber laser randomly selected by Raycus as an example, the measured electro-optical conversion efficiency is over 37%, and the measured data is shown in the figure below.01

12000W power quality analyzer measured data

02

Measured data of 20000W power quality analyzer

*Note: Raycus lasers have a certain degree of redundancy. The actual output power of this 12kW randomly selected is 12.33kW. The actual output power of 20kW is 20.15kW, and the electro-optical conversion rate is the ratio of actual output power to total power consumption.

Today, with continuous breakthroughs in laser technology, the electro-optical conversion efficiency of domestic lasers has been greatly improved. Not only that, but other aspects of performance, including power stability and reliability, are constantly being upgraded, and are no different or even better than foreign brands in practical applications. Recently, a client of Raycus personally tested the electro-optical conversion rate of Raycus and a foreign brand 3000W, 8000W, and 12000W. The machines were randomly sampled, and the following results were obtained:

*Note: Because customers cannot measure the actual output power of the laser, the rated output power is uniformly used here.

It can be seen from the data that the actual electro-optical conversion efficiency of Raycus lasers is comparable to that of imported brands. Regarding the production and operation costs of an enterprise, it is also necessary to comprehensively consider the purchase cost, use cost, after-sales service cost, and policy impact cost.

Raycus has always been adhering to the corporate philosophy of steadfastly making products and serving customers wholeheartedly. Raycus has always been committed to making Chinese high-quality lasers available and affordable to more companies. Even in the current increasingly fierce competition, it still does not change its fundamentals. This is also the main reason why more and more customers identify Raycus.