Efficient, high-quality glass welding

Has always been an important challenge in the field of materials processing

Considered to be a big problem in the welding field

This is mainly due to

Glass materials are hard and brittle and difficult to process

No need to add media

Can directly weld glass

No need to heat the material

Between you and breaking the glass welding problem

Only infrared femtosecond laser

Infrared femtosecond lasers belong to the category of ultrafast lasers. The non-linear absorption effect of transparent materials on infrared femtosecond laser is very suitable for micro welding of transparent materials.

Today, use actual measurement to see how the welding effect is?

Laser and related configuration

Laser parameters

Femtosecond GS-FIR20中心波长

1027nm-1040 nm

Pulse Width

<600 fs

repeat frequency

50-1000 kHz

Maximum single pulse energy

100 uJ

Beam quality M²

≤1.2

Power stability

<3%

Spot diameter

3 mm

*Infrared Femtosecond Laser GS-FIR20 of Gauss Laser

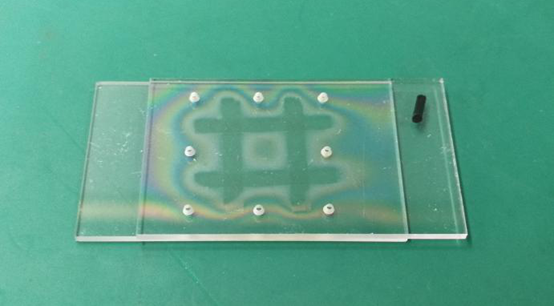

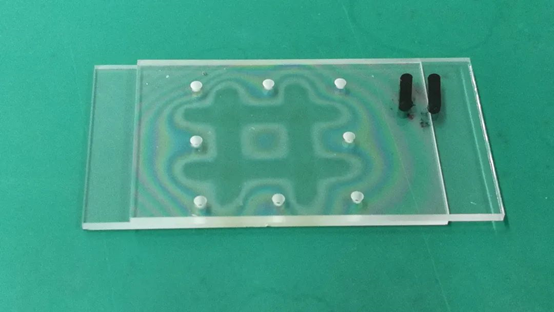

Welding material: 1mm thick soda lime glass

After welding, the two pieces of materials are tightly combined, and the weld is invisible to the naked eye; under a high-power microscope, the weld is uniform and has no cracks, and no additional stress is generated inside the material.

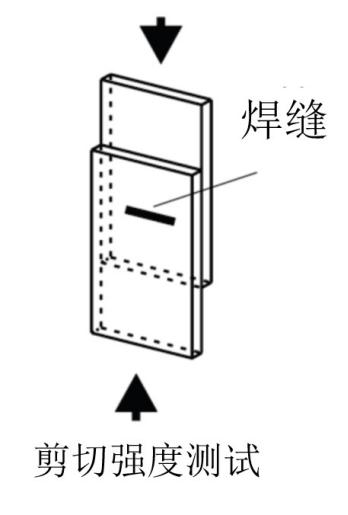

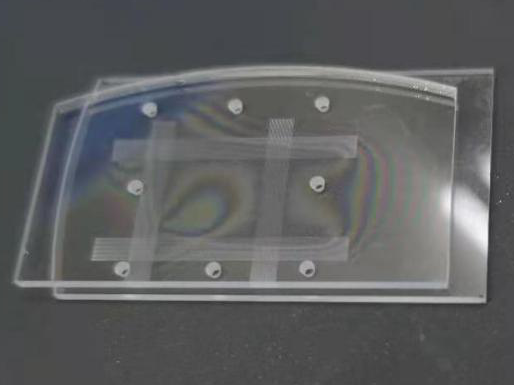

Subsequently, we used a tensile machine to test the shear strength of the glass after welding:

Schematic diagram of tensile test

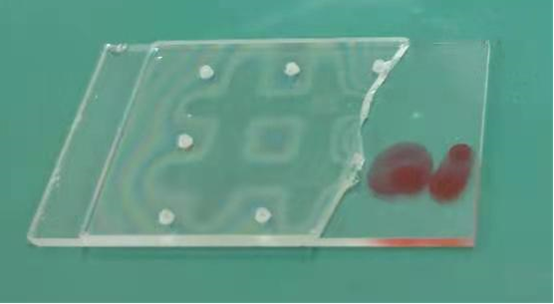

Broken glass

But there is no damage to the welding area

result

The test shows that the bonding strength of the material in the welding area exceeds the strength of the glass itself, so the bonding force of the two glass materials at this time is greater than the value displayed by the tensile machine (282.5N).

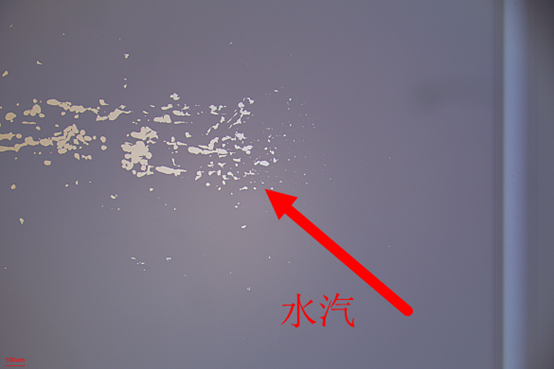

In order to test the sealing performance after welding, the material after welding is soaked in water for a week before taking it out. It is observed that no moisture in the welding area indicates good sealing performance:

The picture shows the welding sample, indicating that the test sealing is qualified

The picture shows the effect of unqualified sealing

Infrared femtosecond laser welding transparent and brittle materials can achieve processing effects that hardly affect the light transmittance of the material, good sealing, and high connection strength.

In addition to soda-lime glass, ultrafast lasers can also realize welding between dissimilar transparent materials, transparent materials and non-transparent materials. This technology can be applied to the connection of wafers and the sealing of precision devices such as semiconductor sensors, micro-electromechanical systems, and solar cells.

Sample|Welding of quartz glass

Sample|Soda-lime glass and sapphire welding

Sample|Welding of soda lime glass and silicon wafer

Ultra-fast lasers provide a more accurate, more efficient and higher-quality processing method for glass welding. It can be expected that after breaking the glass welding problem, it will have a lot to do in the electronics, engineering, and medical fields such as implantable devices and sensors.