With the development of new material processing technology, plastic products have largely replaced traditional materials such as metals and ceramics due to their light weight, high specific strength, corrosion resistance, good insulation and excellent molding performance. It is widely used in aviation, shipbuilding, automobile, medical equipment, food packaging, daily chemical industry and other fields.

Therefore, the quality of the connection process of plastic parts is of great significance to the wide application of plastic products. The existing plastic welding methods include hot plate welding, vibration welding, ultrasonic welding, laser welding, etc., and laser welding has unique advantages because of its precise and firm welds and less resin degradation during the welding process.

Principles of Plastic Laser Welding

Plastics can be divided into two categories: thermoplastics and thermosetting plastics according to their heated properties. Thermoplastic molecules have a linear structure, which softens or melts when heated, and can flow into shape, and become hard after cooling. This softening and hardening process can be repeated, so thermoplastic materials can be connected by welding.

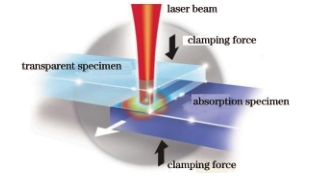

The laser plastic welding method requires that the upper and lower layers of materials to be welded have better permeability and better absorption for a certain wavelength of laser light. Based on this, plastic laser welding is also called laser transmission welding. The principle of laser welding is shown in Figure 1

Figure 1 Principle of laser transmission welding

During welding, the laser penetrates the upper material and is absorbed by the lower material at the joint surface of the upper material and the lower material to generate heat. The heat is transferred between the upper and lower materials to melt the joint surface, and the plastic macromolecules in the molten state are under pressure. Under the action of thermal expansion and mutual diffusion and entanglement, van der Waals force is generated to realize welding.

Generally speaking, when the laser transmittance of the upper material is higher than 50% and the laser transmittance of the lower material is lower than 20%, better results will be obtained.

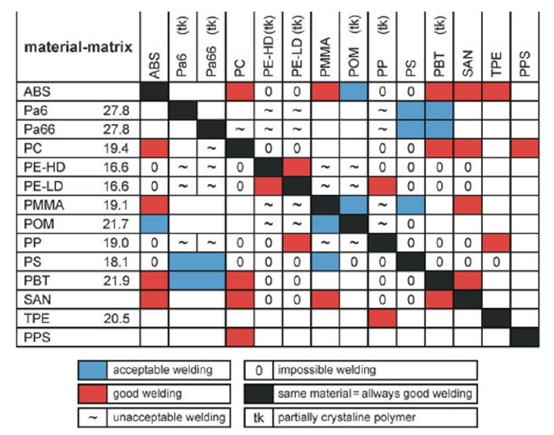

The research and application of laser plastic welding have been carried out abroad since 1972. The domestic start is relatively late, but in the past two decades, this technology has also been studied and applied in depth. Table 1 shows the weldability of commonly used plastic materials.

Table 1 Solderability of commonly used plastic materials

Plastic laser welding method

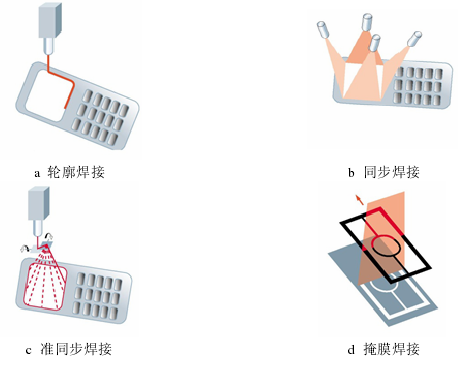

Laser welding methods are mainly divided into four categories: contour welding, synchronous welding, quasi-synchronous welding and mask welding, as shown in Figure 2.

Figure 2 Classification of laser welding methods

The choice of laser

The earliest lasers used in plastic welding are mostly CO2 lasers with a wavelength of 10.6μm. Due to the long wavelength, low penetration and high absorption rate, CO2 lasers are only suitable for welding thin film materials. Compared with CO2 lasers, since most plastics have extremely high transmittance in the 808-1100nm band, semiconductor lasers are widely used in the welding of plastic products.

Selection of process parameters

In the laser welding process, the five factors of the structure of the welded parts, the clamping force, the laser power, the welding speed and the size of the light spot have a great influence on the welding effect. The power used for welding is generally 10W~100W, and the spot size is generally 0.5mm~5mm.

Products Recommended

Raycus hundred-watt fiber delivered diode laser has been widely used in plastic laser transmission welding.

hundred-watt fiber delivered diode laser

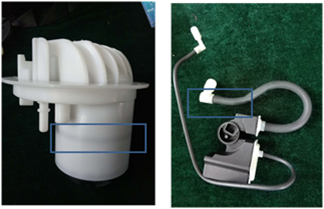

Welding case

White PP+Black PP welding

PA66+GF30 welding

Other plastic welding