Good effect, high efficiency, long service life, no damage to the substrate, and no consumables are the advantages of laser cleaning. It is also the main reason why many people choose laser cleaning instead of traditional cleaning methods.

However, special lasers for laser cleaning have a variety of specifications. In addition to different powers, core diameters and spot modes are also different. The purpose is to customize more suitable products for different application scenarios. Which laser cleaning solution is more suitable for you?

01

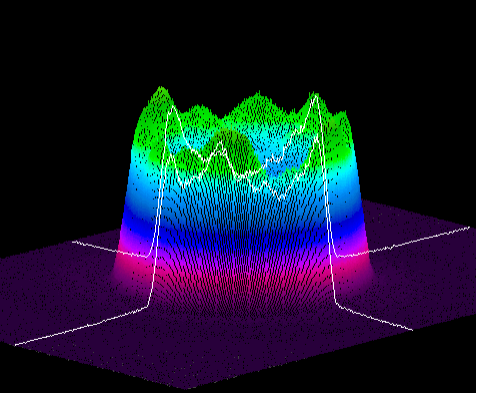

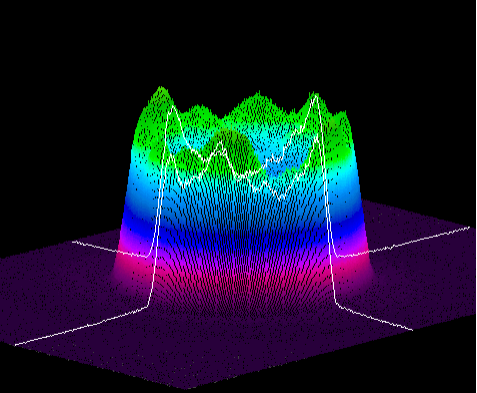

RFL-P100M

Power: 100W

Core diameter: 30μm with light grid

Spot mode: circular spot, Gaussian beam

Industry Application

● Floating rust cleaning of precision parts;

● Pre-welding and post-welding treatment of aluminum alloy and stainless steel;

● Metal parts (copper, aluminum, stainless steel, etc.) oxide layer removal.

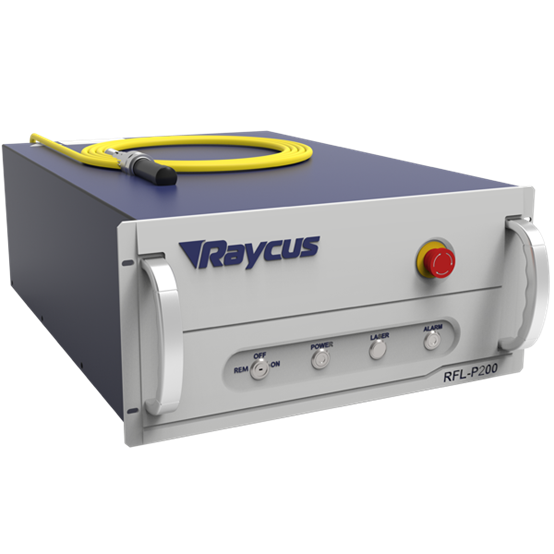

02

RFL-P200S

Power: 200W

Core diameter: 30μm with light grid

Spot mode: circular spot, Gaussian beam

Industry Application

● New energy power battery pole post cleaning before welding and liquid injection port cleaning;

● New energy pole ear cutting;

● Pre-weld and post-weld treatment of car body in white;

● Aluminum alloy pre-welding and post-welding treatments for lightweight body manufacturing of high-speed trains

● Treatment of various metal parts before and after welding.

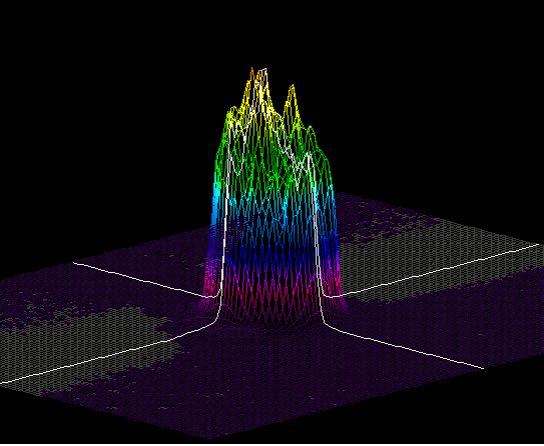

03

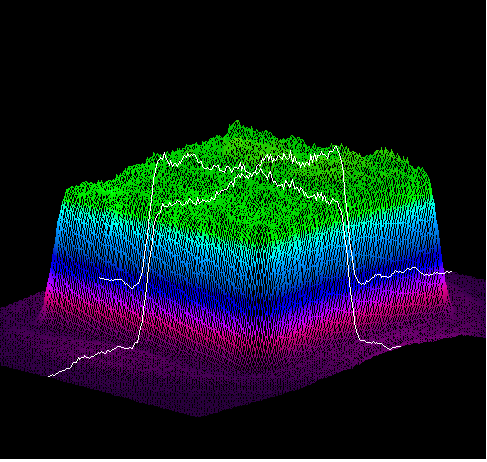

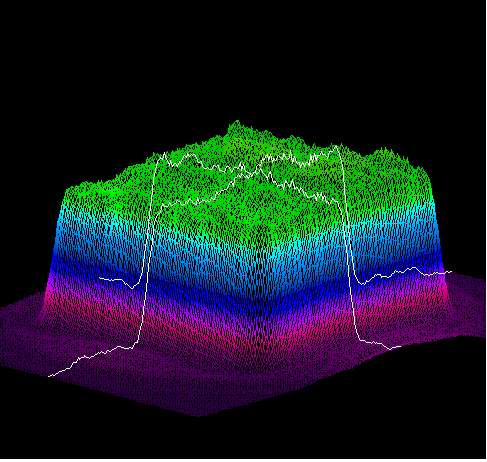

RFL-P200

Power: 200W

Core diameter: 100μm

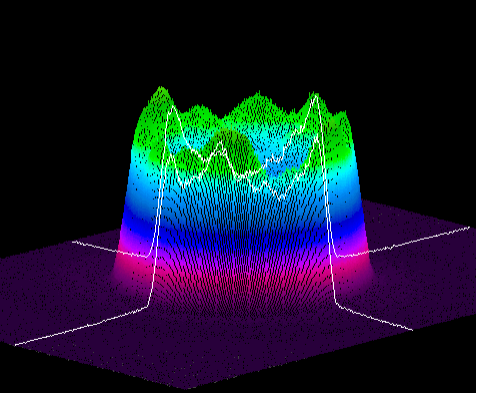

Spot mode: square spot, flat top beam

Industry Application

● Cleaning of aircraft casing and wing coating;

●Car parts, mold surface carbon, rust oil cleaning;

● Cleaning of splicing welds, welding fumes and welding slag on the surface of container thick steel;

● Titanium alloy oxide layer and weld cleaning in shipbuilding industry.

● Efficiency range: 1-5m²/h

● Cleaning the surface condition: In addition to cleaning the corresponding surface coating, it is also necessary to ensure that the surface cleaning condition is uniform, the color and flatness are not different, and there is no heat accumulation temperature influence.

Laser cleaning of container thick steel weld bead

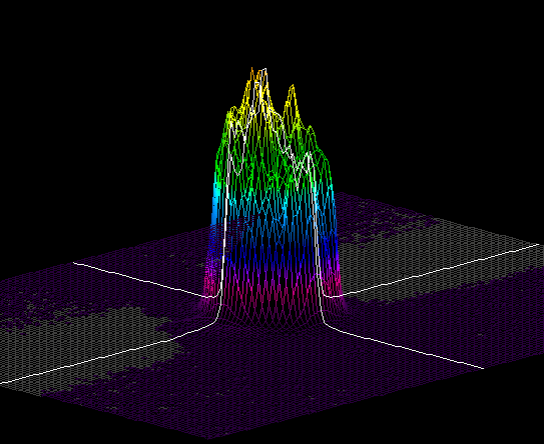

04

RFL-P300

Power: 300W

Core diameter: 100μm

Spot mode: square spot, flat top beam

Industry Application

● Cleaning of aircraft casing and wing coating;

●Car parts, mold surface carbon, rust oil cleaning;

● Cleaning of splicing welds, welding fumes and welding slag on the surface of container thick steel;

● Titanium alloy oxide layer and weld cleaning in shipbuilding industry.

● Efficiency range: 2-6m²/h

● Cleaning the surface condition: In addition to cleaning the corresponding surface coating, it is also necessary to ensure that the surface cleaning condition is uniform, the color and flatness are not different, and there is no heat accumulation temperature influence.

05

RFL-P500

Power: 500W

Core diameter: 200μm

Spot mode: square, round spot can be customized, flat top beam

Industry Application

● Carbon cleaning of steel mold and aluminum mold surface in tire industry;

● Large-scale oil cleaning of auto parts;

● Cleaning the surface of the vulcanizing machine in the electronics industry;

● Surface coating cleaning of large parts and special-shaped parts.

● Efficiency range: 5-10m²/h

● Cleaning the surface condition: In addition to cleaning the corresponding surface coating, it is also necessary to ensure that the surface cleaning condition is uniform, the color and flatness are not different, and there is no heat accumulation temperature influence.

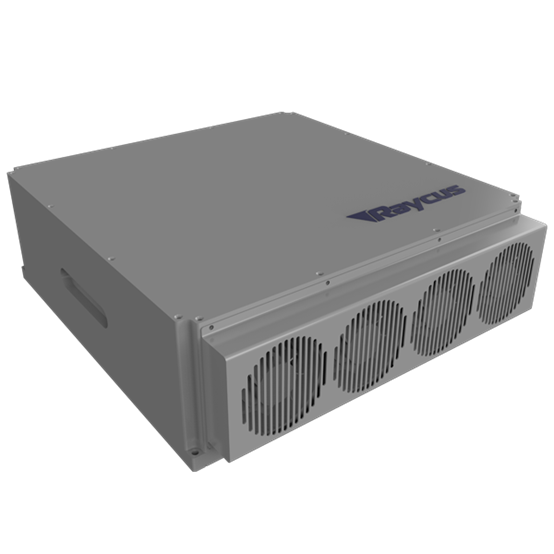

06

RFL-P1000

Power: 1000W

Core diameter: 400μm

Spot mode: square, round spot can be customized, flat top beam

Industry Application

● Carbon cleaning of steel mold and aluminum mold surface in tire industry;

● Large-scale oil cleaning of auto parts;

● Cleaning the surface of the vulcanizing machine in the electronics industry;

● Surface coating cleaning of large parts and special-shaped parts;

● Clean up road markings.

● Efficiency range: 8-16m²/h

● Cleaning the surface condition: In addition to cleaning the corresponding surface coating, it is also necessary to ensure that the surface cleaning condition is uniform, the color and flatness are not different, and there is no heat accumulation temperature influence.

07

RFL-P2000

Power: 2000W

Core diameter: 400/600μm

Spot mode: square, round spot can be customized, flat top beam

Industry Application

● Aircraft skin cleaning;

● Hull anti-rust paint cleaning;

● Bridge maintenance;

● High-speed rail body paint removal.