Why do companies choose 10,000-watt laser processing equipment? In the case of the same processing effect, a faster processing speed is required. Faster processing speed means stronger earning power! Today I will talk about the relationship between processing speed and laser.

The key factor that determines the processing speed is high beam quality, so higher beam quality is the technical challenge faced by core light source laser companies.

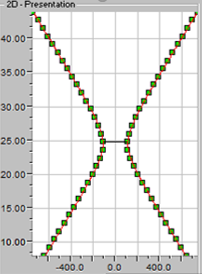

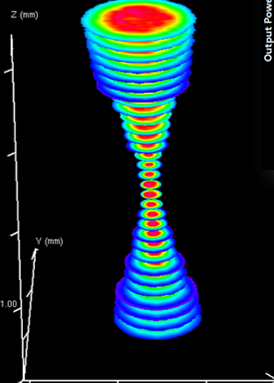

Theoretically, the smaller the value of the beam quality BPP, the higher the power density and the stronger the penetration ability of the beam. BBP=θ×ω, θ is the divergence angle, and ω is the beam waist radius. And ω is proportional to the output fiber core diameter, that is to say, when the divergence angle θ is constant, the smaller the fiber core diameter, the smaller the value of the beam quality BPP (or M²). Therefore, in order to improve the beam quality, laser manufacturing is constantly pursuing the use of fibers with smaller core diameters.

Three difficulties for 10,000-watt lasers to achieve small fiber cores

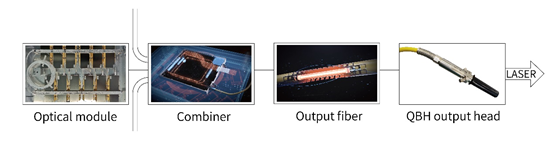

Laser transmission path in fiber laser

Difficulty 1: Realize the unit module with small fiber core and high power

Increasing the power of the unit module while reducing the core diameter will increase the energy density of the transmitted laser. However, when the transmitted laser power reaches a certain threshold, it will produce nonlinear effects, increase transmission loss, affect the beam quality of the final output beam, and reduce the safety and stability of the device.

Raycus new generation of high-power small-fiber core unit module technology has accumulated research on non-linear effects, mode degradation, and large-mode field high-absorption gain fibers. It can further reduce the core of its optical fiber while realizing the output of the high-power unit module.

Difficulty 2: Increase the maximum power of the fiber combiner

The accumulation of thermal effects under high-power transmission will seriously affect the reliability of the fiber combiner, and the thermal effect of a smaller fiber core is more obvious. Therefore, how to increase the maximum power of the combiner is one of the difficulties in the manufacturing of the fiber combiner.

Raycus adopts mature high-power fiber bundle taper technology to couple multiple medium-power fiber lasers into one fiber for output, to obtain greater power while reducing thermal effects and ensuring that the beam quality is not affected. Raycus has significant technical advantages in realizing high-power small-core fiber combiners, and has obtained invention patents and utility model patents.

Difficulty 3: Upgrade high-power transmission component technology

For lasers with higher power and smaller cores, the positive output of the high-power output optical cable and the feedback light generated during use make it difficult to solve the problem of internal heating of the output head of the output optical cable. Therefore, the research on the water-cooling technology inside the output optical cable is particularly urgent. In addition, issues such as transmission fiber and end cap processing technology, end cap coating technology and end cap damage threshold are also the key to achieving high power output with small fiber cores.

Raycus adopts high damage threshold small-core transmission fiber technology and end cap technology to ensure the development and manufacture of small-core output fiber optic cables, and it is also the key to ensuring that Raycus high-power fiber lasers can achieve small-core output.

Raycus laser core size introduction

The output core size of the 4kW-20kW standard model is 100μm; (other core diameters 200/300/400/600μm can be customized)

The output core size of the 30kW standard model is 200μm, which can be 150μm.

The 1500W/2000W/3000W standard model has an output core of 50μm, other core diameters can be customized.

The standard model of 1000W and below has an output fiber core of 25μm, which has been customized for customers to 14μm, and other core diameters can be customized.

Raycus beam combining technology and the advantages of fiber quality make the core diameter of Raycus high-power products smaller. For example, the 20kW Raycus fiber core achieves 100μm, which is ahead of other domestic brands. According to customer site measurements, Raycus’ 20kW laser, in the case of air cutting stainless steel and carbon steel, has an average cutting speed of 10% higher than other products with a 150μm core, which means that it can increase production by 10% per day for processing enterprises.