With the development of laser technology, the exquisite, permanent, efficient, and pollution-free laser marking process,

It is widely used in daily life products and is rapidly replacing traditional coding technology.

With the increasing demand for miniaturized device processing,

Ultra-fast laser field UV picosecond laser,

Makes a finer and more precise marking process possible

With UV picosecond laser marking, how precise can be achieved? We will call you on the spot today!

Prepare materials

1 50um thick stainless steel

2 4mm×1mm D-shaped code (Datamatrix code is a matrix type two-dimensional barcode, which has the characteristics of high density, small size, large amount of information, etc.)

3 15W UV picosecond laser

Laser and related configuration

Laser model GS-PUV15

Center wavelength 355±0.2nm

Maximum output power (W) 15W

Pulse width <12 ps

Repetition frequency 400-1000 kHz

Maximum single pulse energy 37.5 uJ

Spot ellipticity >85%

Divergence angle <0.2mrad

Beam quality M² ≤1.2

Power stability <1%

Spot diameter 2±0.3 mm

*GS-PUV15 is a UV picosecond laser of Gausslaser

Macroscopically, it can be seen from the picture that the marking position and edges are not deformed, and there is no crease on the back:

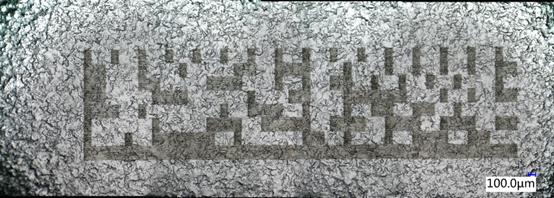

Using a 3D microscope to observe the microscopic appearance of the QR code, you can see that the lines are uniform, the measured line width is about 0.01mm, and there are no metal particles between the lines:

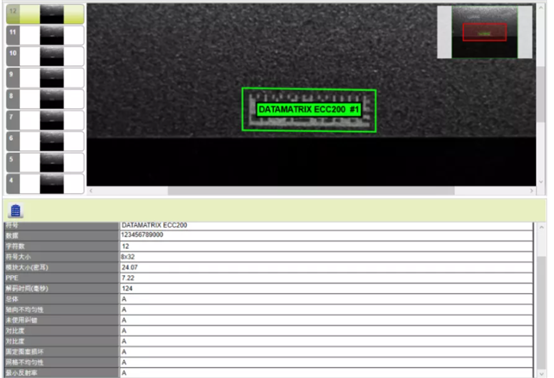

Use the micro code reading system to read the D-shaped code and determine the reading level:

It can be seen from the code reading interface that the overall evaluation level is determined to be A level by comprehensively evaluating the axial instability, contrast, fixed pattern damage, and minimum reflectivity of the two-dimensional code.

The final coding effect:

1) There is no trace on the back;

2) There is no deformation of the marking position and the edge;

3) No metal particles.

4) The scan code level reaches the highest level A;

Compared with the traditional laser marking of two-dimensional codes, the UV picosecond laser can act on the surface of the material with a very thin beam, and the smallest line width can reach 0.01mm or less, which can realize the marking of thinner materials with higher precision and smaller heat affected zone has a higher scanning code level. It creates a broader application space for precision processing and anti-counterfeiting functions.