Have you ever encountered these situations?

- Rough cutting surfaces with severe dross, requiring time-consuming secondary processing?

- Molten slag always sticking during small hole cutting, compromising precision?

- Still can't achieve a clean cut after repeated adjustments, causing productivity to plummet?

Dross issues might seem minor, but they cause major headaches!

They not only affect product appearance but also reduce capacity and increase costs.

Don't worry! We've prepared this 【Laser Cutting Dross First-Aid Guide】 for you.

Follow these 4 routine troubleshooting steps to achieve perfect cuts that meet requirements!

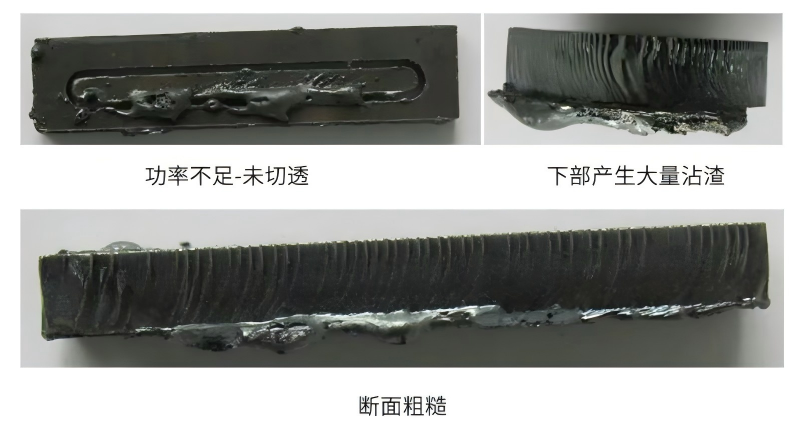

Check Output Power

Problems:

Insufficient power fails to cut through, causing molten residue to accumulate into bumps.

Excessive power widens the kerf and roughens the cutting surface.

Problems occurring when laser power is insufficient for cutting mild steel plate

Solution: Readjust and set appropriate laser output power based on material type and thickness.

TIPS: "Targeted solution" – power is the foundation.

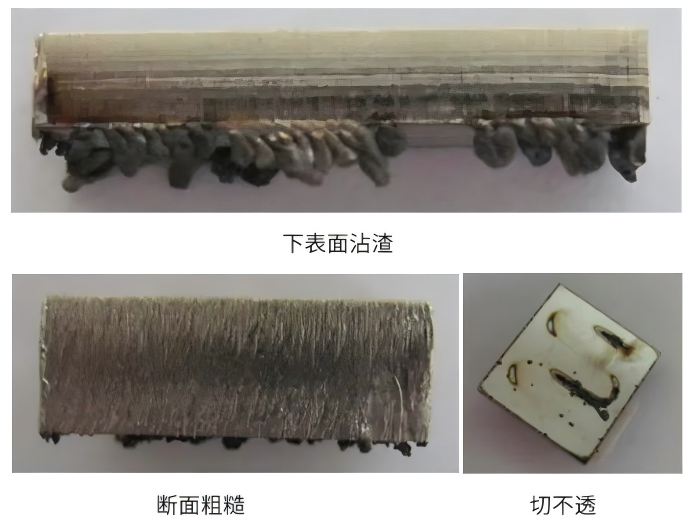

Check Gas Pressure

Assist gas (e.g., O₂, compressed air, N₂) is crucial in laser cutting – it blows away molten slag and cools the kerf, effectively protecting material properties. For materials like carbon steel, oxygen is recommended as it reacts with metal to improve cutting speed and efficiency.

Problems:

Excessive assist gas pressure causes vortices on the material surface, reducing molten material removal ability, resulting in wider kerfs and rough surfaces.

Insufficient pressure fails to completely blow away molten material, causing slag adhesion on the lower surface.

Solution: Adjust assist gas pressure (O₂, N₂, air, etc.) to find the optimal value that steadily removes slag.

TIPS: Gas is the "scavenger" – its force must be just right.

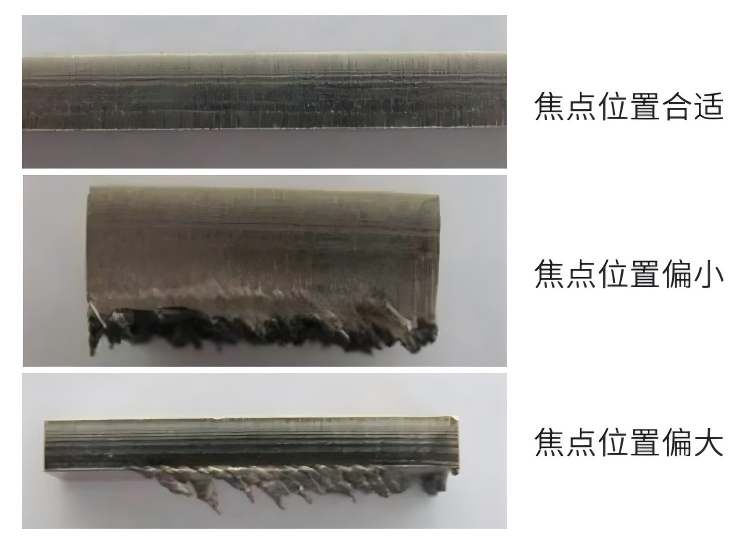

Check Focus Position

Problems:

- Too advanced focus causes the lower part of the workpiece to absorb excessive heat, making melted material flow liquid along the lower surface and solidify into spherical dross.

- Too delayed focus prevents the lower material from absorbing enough heat, leaving incomplete melting with sharp, short residue adhering to the lower surface.

Note: Focus position (distance from laser focus to workpiece surface) directly affects surface roughness, kerf taper, and width.

Solution: Check and adjust the focus position based on offset measurements to ensure laser energy concentrates at the optimal height.

TIPS: Focus is the "energy point" – a minute error leads to major defects.

Check Cutting Speed

Cutting speed directly affects processing efficiency and quality, requiring precise settings based on material and thickness. Either too fast or too slow speeds cause rough surfaces and dross defects. Only appropriate speed ensures both cutting efficiency and quality.

Problems:

Too fast: sparks deflect, material isn't fully burned, leaving dross.

Too slow: excessive heat buildup, oversized molten kerf, rough surface.

Defects from improper cutting speed

Solution: Precisely adjust cutting speed. Observe cutting sparks: normally, flames spread downward. Deflected flames indicate excessive speed; condensed, non-spreading flames indicate insufficient speed. Proper speed shows stable drag lines on the cutting surface without lower slag.

TIPS: Speed is the "pace setter" – must be just right.

【Quick Reference Guide】With Actual Photos of Cutting Defects

Stainless Steel Cutting Defects

Defect Photo

Possible Causes

Solutions

Speed too high

Focus too low

Power too low

Reduce speed

Adjust focus position

Increase power

Center misalignment

Nozzle clogged or out-of-round

Optical path misalignment

Check center alignment

Check nozzle condition

Check and adjust optical path

Focus too low

Raise focus position by 0.1-0.2 mm increments

Nitrogen pressure too low

Increase nitrogen pressure

Focus too high

Lower focus position by 0.1-0.2 mm increments

Cutting speed too high

Reduce speed by 50-200 mm/min increments

Focus too low

Raise focus position by 0.1-0.2 mm increments

Low nitrogen purity

Oxygen or air in gas line

Check nitrogen purity

Increase purge time to clean gas line; Check gas line for leaks

Carbon Steel Cutting Defects

Defect Photo

Possible Causes

Solutions

Lens center misalignment

/Nozzle clogged or out-of-round/

Optical path misalignment

Check lens center alignment

Check nozzle condition

Check and adjust optical path; Re-calibrate beam alignment

Incorrect lead-in length or type

Incorrect cutting path type

Piercing time too long

Excessive heat during cutting

Correct lead-in type and length

Check cutting path type

Reduce piercing time to ≤2 sec

Reduce peak power by 2-3% increments

Pressure too high

Focus too high

Power too high

Material quality issue

Reduce pressure by 0.1 bar increments

Reduce power

Check lens focus position

Power too low

Speed too high

Pressure too low

Increase power

Reduce speed

Increase pressure

Speed too high

Power too low

Reduce speed.

Increase duty cycle by 5-10% increments.

Increase power in 100W steps; Increase pressure by 0.1-0.2bar increments.

Localized overheating

Material issue

Change cutting sequence

Replace material

Pressure too high

Reduce speed

Reduce pressure by 0.1-0.2bar increments

Focus too low

Pressure too low

|

Raise focus by 0.1-0.2mm increments Increase pressure by 0.1-0.2bar increments |

(Some images are sourced from the internet; contact for removal if infringing.