The second Shenzhen International Lithium Battery Technology Exhibition was held in Shenzhen Expo Centre from Dec. 10th to 12th .

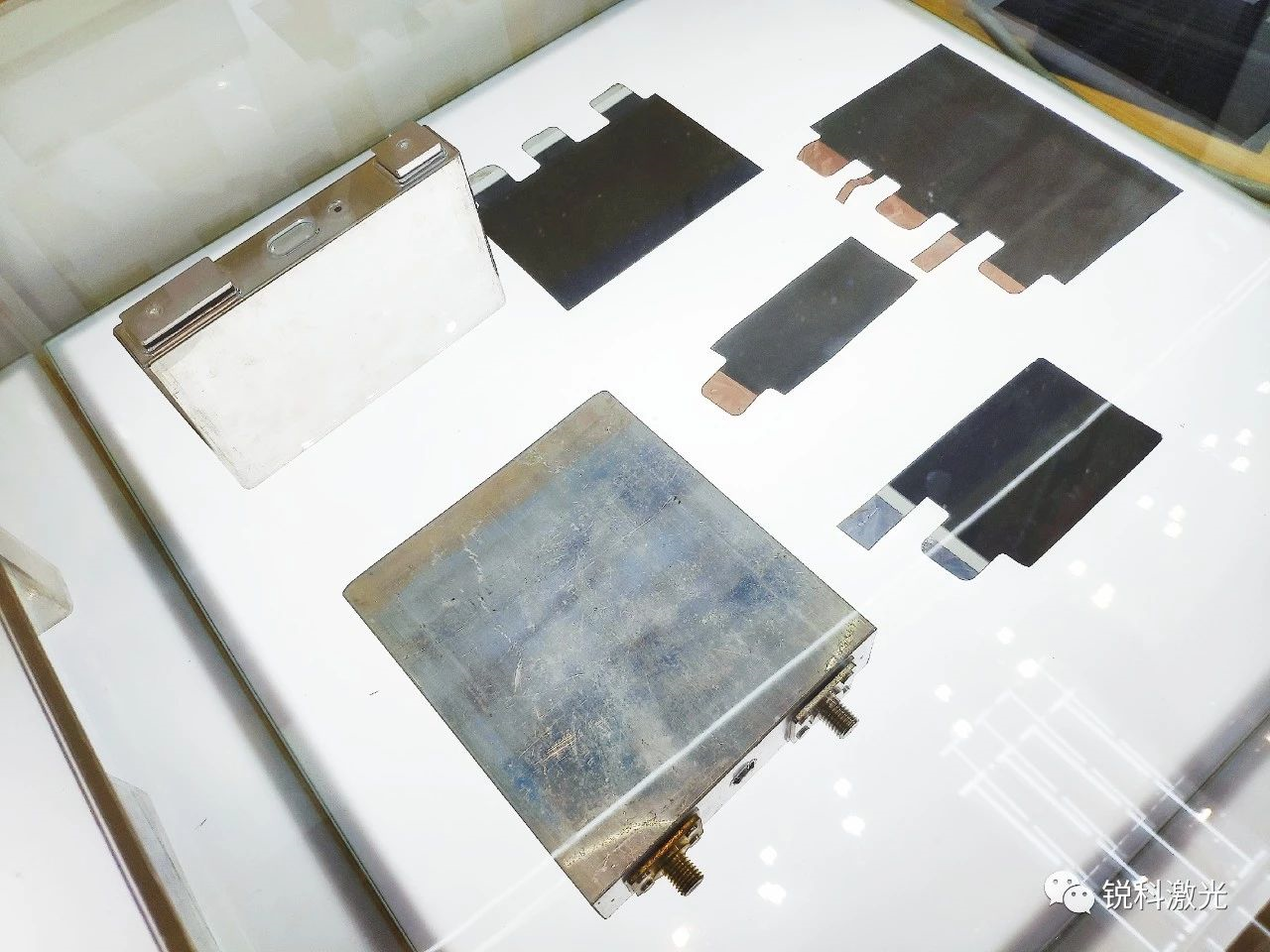

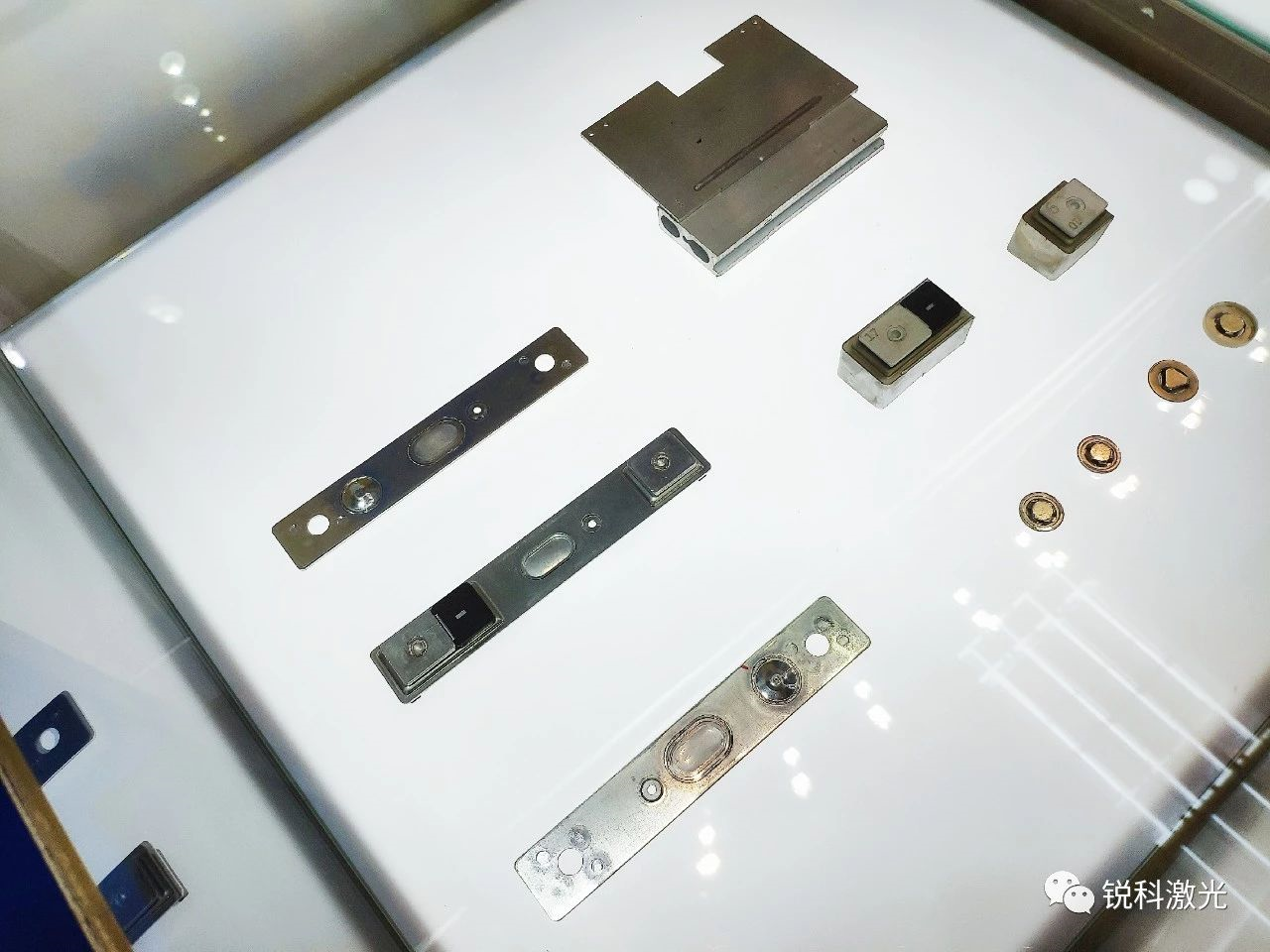

Raycus showed various laser solutions for power battery manufacturing applications, including power battery pole cutting, explosion-proof valve, peripheral sealing, soft joint welding, surface marking, hard hat, battery level with fine processing etc. , as well as other innovative products, live demonstrations and some delicate samples.

So, what are the requirements for the selection of fiber lasers for welding different parts of the power battery?

What is the advantage of laser welding?

And what kind of effect is the actual solution and case?

Rayclass: Using 4kW fiber laser on battery module side plate welding

Power Battery

The power battery refers to battery applied to electric vehicle, it has large storage capacity and output power, and can be used as driving power source for electric vehicle.

At present, the power battery commonly used in the market is lithium battery (battery pack), which has many manufacturing processes. Among them, there are explosion-proof valve seal welding, tab welding, soft joint welding, helmet welding, housing sealing and sealing welding, module welding, PACK package welding, electrode pole welding, bus bar welding, etc., which are required for laser welding. The materials are mainly pure copper, aluminum and aluminum alloy, stainless steel, etc.

1000W-2000W Welding Solution

The material thickness of explosion-proof valves, tabs, helmets, housing seals, electrode posts and other components is generally small, usually between 0.2 and 2 mm. These components are mainly required for sealing or not required for weld strength. The laser power for soldering such components is generally relatively small, and the three lasers of 1000W, 1500W, and 2000W can basically meet the requirements.

Raycus 2kW CW Fiber Laser Appearance

4000W-6000W Welding Solution

The weld depth of the side plates and bus bars of the module is generally between 2 and 4 mm, which requires high weld strength. If the welding is performed with a relatively low power laser, the welding speed will be slow, and even the weld penetration will be deep. Both the intensity and the intensity are not up to standard. Currently, we need to select a laser with a higher power, such as 4000W or 6000W Raycus laser.

|

|

to ensure the weld penetration; |

|

2 |

to ensure relatively fast welding speed and improve production efficiency; |

|

3 |

With the proper welding head, the weld bridging ability can be effectively improved, that is, the tolerance of the assembly gap of the joint can be increased; |

|

4 |

There is a large welding process parameter window, which can ensure a more stable product quality.

|

Practical Example

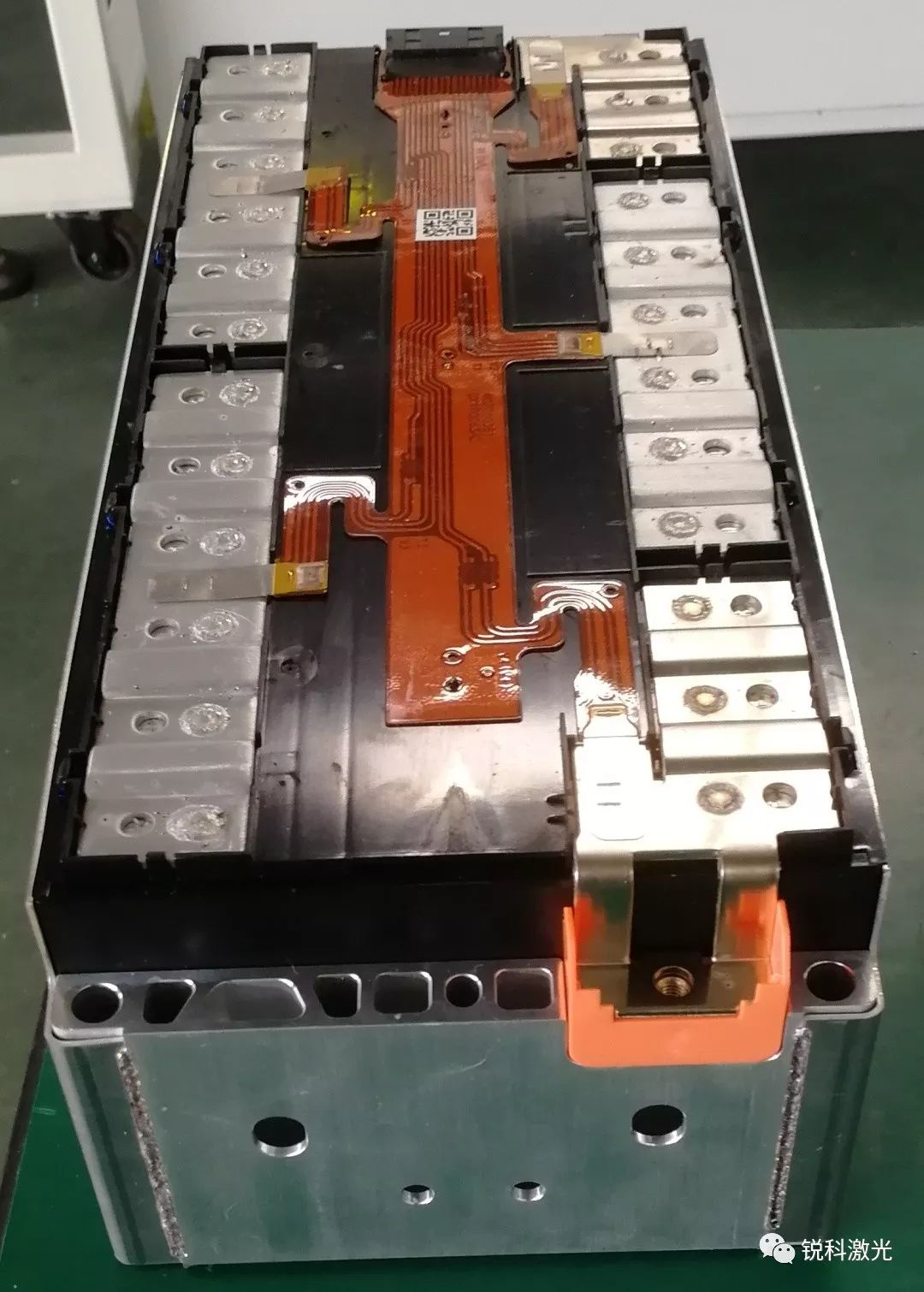

Power Battery Module Side Plate Welding

In the aspect of module side plate welding, the aluminum alloy profiles and plates of the power battery pack are commonly used as the outer frame structure of the module. The quality of the welding determines the rigidity of the overall structure of the module.

Welding Requirements

The weld seam is evenly distributed, the penetration depth is more than 2mm, the weld strength is high, and the strength cannot be broken in the positive seam area.

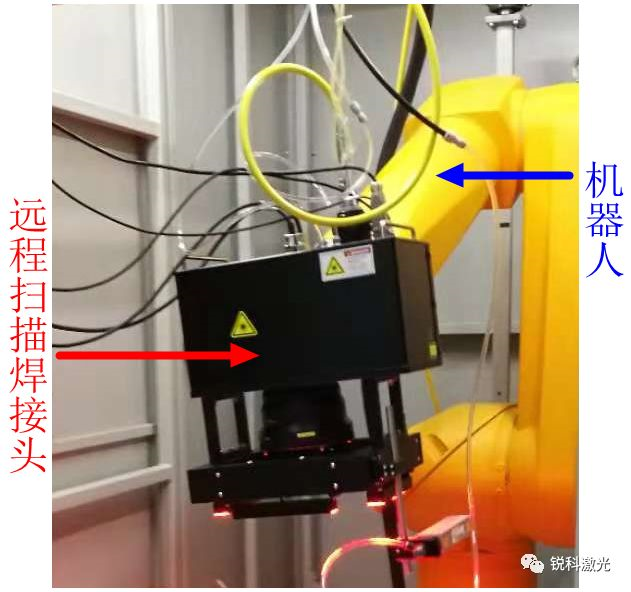

Basic Equipment

4000W fiber laser

remote scanning soldered joint

Welding Platform

Robot

Welding Requirements

Welding Power Welding Speed(m/min)

3600 3.6

Welding Effect

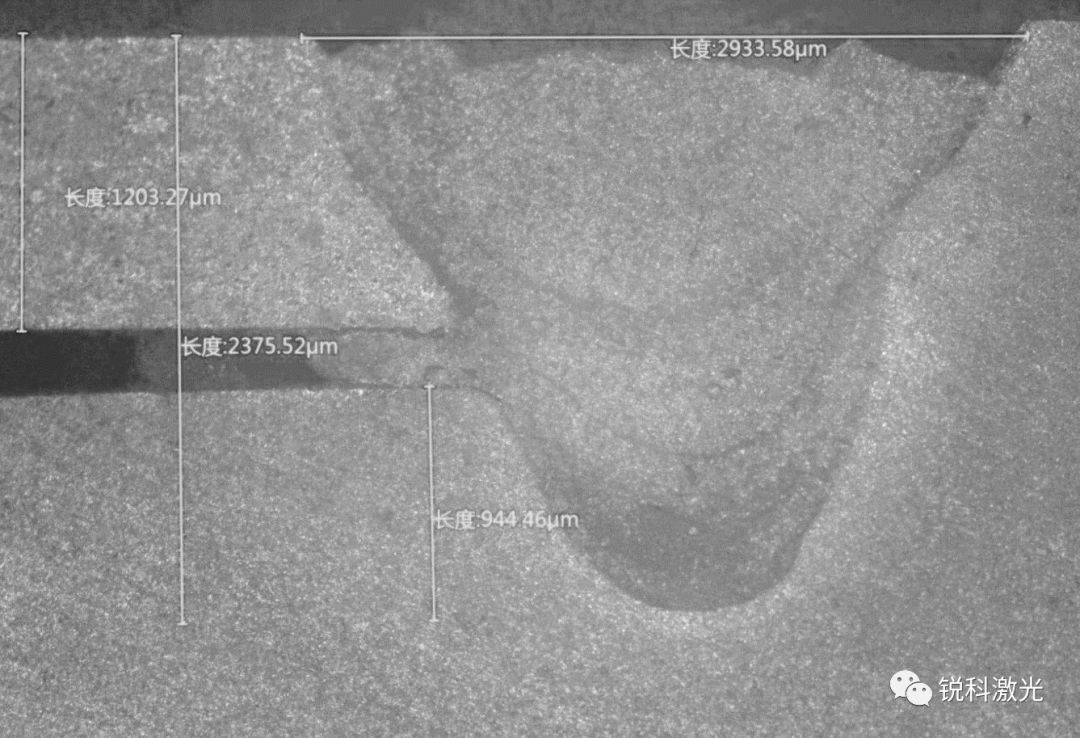

Partial Enlargement

Weld Appearance

Weld Seam Planing

Conducting Weld Cross Section Metallographic Examination

As can be seen from the above figure, the weld width is 2.93 mm and the penetration depth is 2.38 mm. There is no porosity or crack inside the weld, and the weld formation meets the requirements.

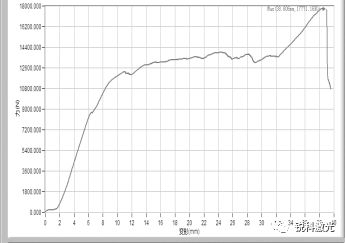

Tensile Test

The tensile test of the weld with a length of 70mm is carried out. The maximum tensile strength of the weld is 17.8KN, and the joint is broken in the heat affected zone of the base metal side, and the welding effect is good.

Tensile Test Curve

The Advantages of 4000W Product Welding

The RFL-C4000 is a 4kW multi-module CW fiber laser independently developed and produced by Raycus.

|

|

The output optical system adopts the output optical fiber with reinforced armor, the output connector is QBH, the beam quality is good, and the welding head of mainstream manufacturers can be configured; |

|

2 |

With a variety of control modes, and has good anti-high performance; |

|

3 |

For the welding of aluminum and copper materials in the power battery industry, it has a strong advantage and has been widely used in the power battery industry. |

Raycus 4000W CW Fiber Laser Appearance

As the laser welding process continues to mature, it can be applied to the field of power batteries , which is for new energy vehicles , are also constantly expanding.

Domestic fiber lasers are emerging rapidly. In the future, Raycus will focus on reducing user costs and improving processing efficiency. For laser applications in the field of intelligent manufacturing on power batteries, development of fiber laser products and solutions for different needs, Raycus will continue to promote the application and development of fiber lasers in the power battery industry.