Intelligent manufacturing represents the main direction of the high-quality development of the manufacturing industry. As an industry where new formats and new technologies are rapidly emerging, how does laser as an advanced processing technology form perfectly integrate into the overall solution of intelligent manufacturing?

Today we came to a certain subway wheelset maintenance workshop to see what kind of sparks the two brought together when laser cleaning technology closely joined hands with "rail transit".

Cleaning before inspection is the top priority

In the process of overhaul and maintenance of rail transit equipment, the vehicle wheels need to be stripped and cleaned before flaw detection. Then transport the bare wheelset to professional flaw detection equipment to check whether there is any crack damage inside the wheelset, in order to find out the potential cracks on the surface of the wheelset.

Wheelset inspection is the top priority of the entire wheelset inspection line. This requires the cleaning process before flaw detection, which must be able to completely remove the paint on the surface of the wheel set and expose the metal surface of the wheel set. Only the cleaned wheel set can meet the requirements of the flaw detection process.

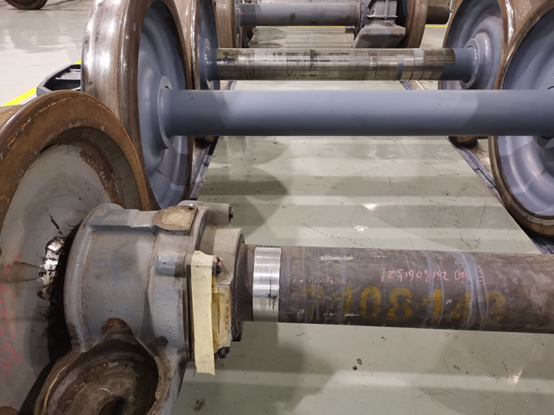

Wheelset waiting to be cleaned

Replace traditional cleaning methods, composite cleaning 1+1>2

Traditional cleaning methods include sandblasting, mechanical polishing, high-pressure water jets, chemical cleaning, and ultrasonic cleaning. These cleanings have problems such as damage to the substrate, poor working environment, pollution, low efficiency, incomplete cleaning of some locations, and high cleaning costs.

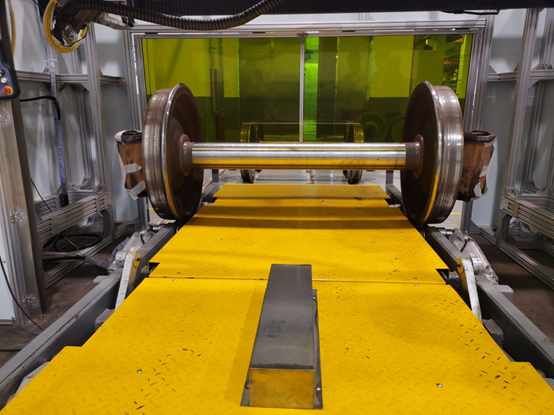

Hangzhou CRRC Digital Technology Co., Ltd. (hereinafter referred to as "CRRC") is now using a fully automatic wheel-set laser paint removal equipment jointly developed with Raycus Fiber Laser. It adopts a fully automatic pass-through design and uses laser technology as the core. Laser composite cleaning that combines the advantages of pulsed lasers and semiconductor lasers to achieve a cleaning effect of 1+1>2.

Wheel set being cleaned

Wheel set after cleaning

After cleaning and flaw detection, the repainted wheel set

Environmental protection, health, effectiveness and efficiency fully up to standard

According to Mr.Wang, the person in charge of the Hangzhou CRRC project, when the vehicle is overhauled or erected (for example, after running for 5 years or 600,000 kilometers), the wheelset will be returned to the warehouse for paint stripping and flaw detection. "Traditional paint stripping uses chemical reagents, no matter from the perspective of environmental protection or worker health, new technical means are urgently needed to replace them."

This composite cleaning equipment can efficiently complete the cleaning operation while ensuring environmental friendliness. It has the characteristics of convenient operation, good cleaning quality and high safety, and does not damage the substrate after cleaning. At present, the equipment can be cleaned within 25 minutes for the original painted wheelsets, and the post-painted wheelsets can be cleaned within 15 minutes, and the cleaning effect and efficiency can fully meet the requirements of subsequent flaw detection procedures.

Reliable and Trustworthy

When it comes to why we chose Raycus Laser to jointly develop this cleaning equipment. Project leader Wang Gong said, “I first encountered laser applications and did a lot of research in the early stage, and chose Raycus as the leader in the laser industry. At the beginning it was found that Raycus marketing and operating were very professional. It took more than a year to jointly develop this domestic first automatic wheelset laser paint removal equipment, and the use was also very satisfied. I hope that in the future, we can cooperate more deeply to develop smarter laser cleaning equipment with higher power and higher efficiency, fully replacing traditional cleaning methods, and making subway maintenance more environmentally friendly and efficient."

CRRC Hangzhou and Raycus reached a strategic cooperation in laser cleaning

With the rail transit industry as a representative, advanced laser cleaning technology has received more and more attention in the context of the country's vigorous promotion of the transformation and upgrading of the manufacturing industry. The characteristics of green environmental protection, cost reduction and efficiency increase, make laser cleaning the future development trend of industrial cleaning. The successful use of laser cleaning in CRRC Hangzhou also indicates a bright future for laser technology to promote the development of high-tech industries.