Contact letter (laser antifreeze protection)

In the cold winter, when the air temperature is lower than 0 °C, the liquid water will condense to form solid. During the solidification process, the volume will increase, which will crack the pipeline and components in the water-cooling system (The cold-water system includes the chiller, laser, and output head). During the installation and debugging of the laser in your company, pay attention to the filling of anti-freeze fluid before using it. After debugging, the QBH output cable and laser must be filled with anti-freeze fluid and stored or sent to the customer to avoid loss caused by freezing damage during storage and transportation.

How the client avoids laser antifreeze is a key issue in winter laser maintenance. Now we will inform you about the anti-freeze protection measures and hazards of laser in winter, and please remind your customers again to avoid losses.

If there is no power outage in the local area, the night water cooler will not be turned off, and to save energy, the low temperature and normal temperature water temperature will be adjusted to 5~10 °C to ensure that the coolant is in circulation and the temperature is not lower than the freezing point.

Use antifreeze as coolant

Antifreeze must be used when the environment is often blacked out and there are no conditions for daily coolant venting. The base liquid of antifreeze is generally composed of alcohol and water. It requires high boiling point and flash point, large specific heat and conductivity, low viscosity at low temperature, not easy to foam, and does not corrode metal parts and rubber hoses. When selecting or blending antifreeze, the freezing point should be 5 °C lower than the lowest temperature in the environment. When adding antifreeze, you need to check whether the antifreeze is compatible with the water cooler. Some water coolers need to be filled with professional antifreeze.

the choice of antifreeze

Add professional brand antifreeze to the water cooler, such as Clariant AntifrogenN antifreeze, the adding proportion is 3:7 (3 is antifreeze, 7 is water), after adding antifreeze, it can resist -20 °C without freezing. If the temperature is lower than this range, please consult the water cooler supplier to confirm the proportion of antifreeze.

If the professional brand is not convenient to buy, you can purchase a large bottle of anti-freeze shell OAT-45 °C, directly used in the laser cooling system, the dilution ratio can refer to the following table, please use according to the ratio of the actual temperature. Due to the use environment and the configuration of the water cooler, the actual use will affect the coolant flow rate, flow rate, causing the water cooler flow alarm or laser heat dissipation. If the temperature is abnormal, please contact the Raycus technical support of each unit. Any antifreeze cannot completely replace deionized water and cannot be used for a long time throughout the year. After the winter, the pipeline must be cleaned with deionized water or purified water, and deionized water or purified water should be used as a coolant.

|

environment temperature℃ |

Shell OAT-45℃( litre ) |

deionized water (litre) |

Reference specific heat capacity KJ/KG.K |

Special Note |

|

-5 |

0.5 |

1 |

3.757 |

1. The typical value of specific heat capacity of water is 4.2kj/kg.k. The larger the specific heat capacity of antifreeze added, the lower the specific heat capacity of cooling medium and the worse the cooling effect under the same flow rate. It can be added according to the reference ratio. If the conditions permit, you can directly purchase the regular brand antifreeze solution corresponding to the antifreeze level. If you encounter flow alarm, high temperature alarm, etc., you can consult the water cooler manufacturer;2. The various additives that play a protective role in antifreeze products have the minimum content requirements (such as inhibition of volatilization, corrosion prevention, etc.), and may accelerate the aging after dilution with water. It is recommended to replace it once every month. |

|

-10 |

0.8 |

1 |

3.563 |

|

|

-15 |

1 |

1 |

3.55 |

|

|

-20 |

1.5 |

1 |

3.344 |

|

|

-25 |

2.2 |

1 |

3.234 |

|

|

-30 |

4.1 |

1 |

3.111 |

|

|

-35 |

5.8 |

1 |

3.068 |

|

|

-40 |

Do not add water |

1 |

2.844 |

|

|

-45 |

Do not add water |

1 |

2.844 |

Precautions for the use of antifreeze

Any antifreeze cannot completely replace deionized water and cannot be used for a long time throughout the year. After the winter, the pipeline must be cleaned with deionized water or purified water, and deionized water or purified water should be used as a coolant.

Meanwhile, during the holidays such as the Spring Festival holiday or during the long power outage, please drain the water in the pipeline related to the laser and water cooler.

the laser cooling liquid emptying method and pipeline design plan reference

In the extreme cold weather in winter, all cooling water in the laser, laser output head, processing head and water cooler must be cleaned to effectively protect the entire water-cooled pipeline and related components. When transporting the laser, clean air is required to drain the remaining water in the laser.

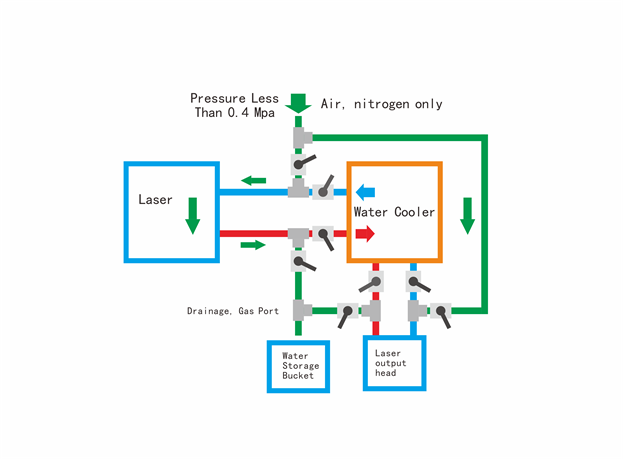

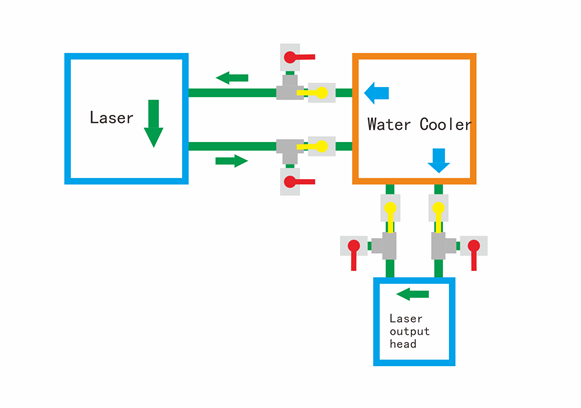

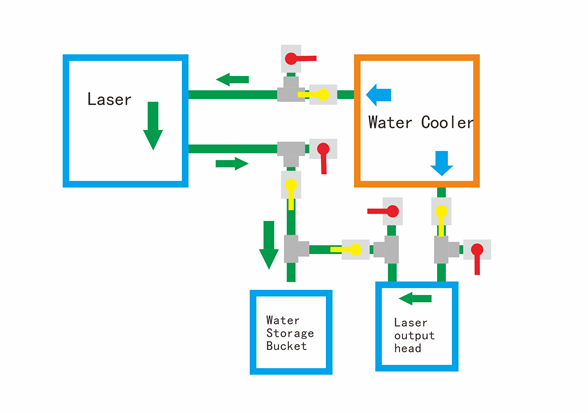

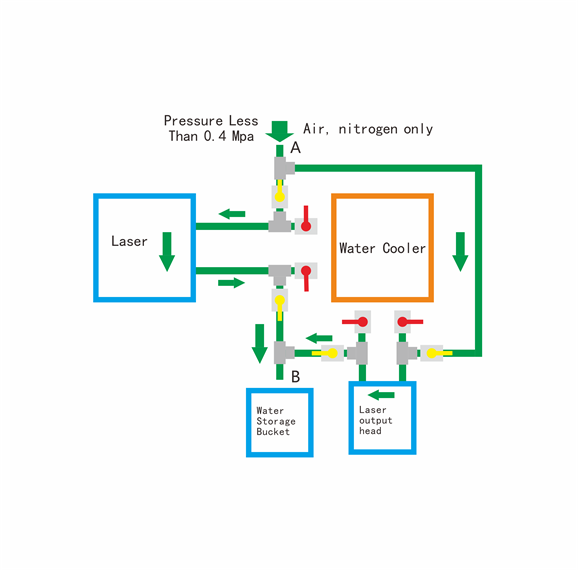

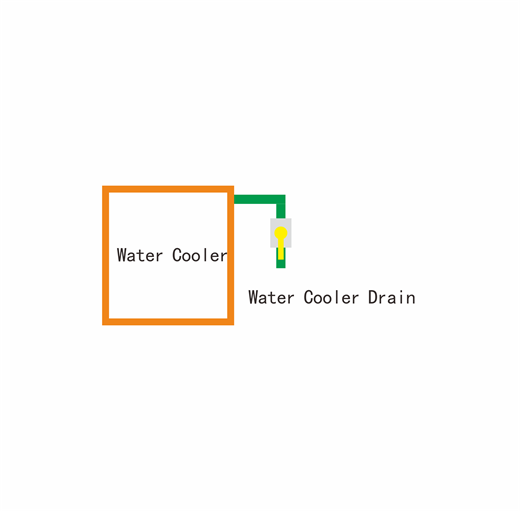

- Waterway connection schematic

Valve status during normal use (red off yellow on)

- use the water cooler to actively empty before shutting down

4、Low pressure air venting residual water

Close the red marked valve as shown in the figure, open the yellow indicating valve, and pass a clean compressed air or nitrogen of not more than 0.4Mpa (within 4kg) to the A, until no water droplets are blown out at the B outlet. Note that water droplets on the tube wall may form ice crystals that impinge on the fiber optic cable and crystals under the influence of water flow. Be sure to ventilate the pipe to no water droplets.

- 5、the water cooler drain is always open

Finally, open the drain of the water cooler to drain the remaining water in the last tank.

- special reminder

Extremely cold weather will cause hard-to-repair damage to the laser optical part. Please be sure to store and use the laser strictly in accordance with the storage temperature and working temperature specified in the laser manual. We must pay attention to prevention and protection work to prevent unnecessary economic losses.