I believe that those who have seen the movie "Fast and Furious 8" must remember this period of remote control of the car in the movie. While enjoying the wonderful movie, they also lament the ubiquity and omnipotence of modern technology.

Of course, today’s topic is not cars, but Raycus fiber lasers and another artifact that can remotely monitor fiber lasers—Raycus Cloud Platform. Next, let us walk into the Raycus cloud platform to see what functions this artifact has and what benefits it can bring to you.

Your laser stewards

As the heart of a processing equipment, the operating status of the laser directly affects the efficiency of the equipment. Real-time monitoring, rapid alarm, remote diagnosis, problem locking, remote guidance or immediate dispatch, problem solving and a series of operations, Raycus cloud platform services can help you handle the whole process like a housekeeper, saving you time and effort.

● You can view the laser's operating status in real time through your mobile phone or computer, and view the laser's health status, including the output power, laser temperature, water flow status, etc., to escort your production process;

● Through the laser’s power-on time and today’s light-emitting time, you can obtain the frequency and duration of laser use, and estimate the utilization. Provide data support for production capacity;

● Once the laser is running abnormally or there is a potential risk of shutdown, the machine will automatically send an alarm message to the cloud service platform. Raycus professional after-sales engineers will receive the information as soon as possible and quickly diagnose the cause of the abnormality, and quickly make feedback and actions. On the one hand, it promptly reminds the troubles before they happen, on the other hand, dispatches workers nearby to shorten the maintenance time, reduce the user's downtime loss, and reduce the maintenance cost.

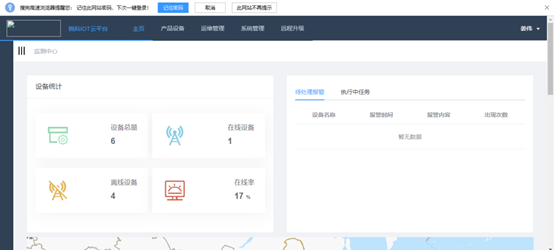

Interface effect

On the large screen full of scientific and technological data, you can view the total number of lasers, the number of devices currently online and offline, the percentage of the number of normal and abnormal lasers, the distribution area of customers, the type of industry, and so on in real time.

The operating status of the laser is uploaded to the Raycus cloud server in real time through the built-in 4G communication module. End customers, integrators, and Raycus service engineers can log in to the smart cloud service platform through their own accounts to view their own laser status, parameters, etc. information.

Interface after successful login

You can see all the lasers you own in the equipment product item

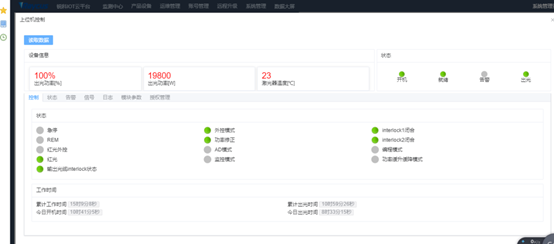

Enter the laser control page to view the operating parameters of the laser in real time

Can see today's turn-on time and light time

Maintenance interface

Take a laser as an example, as shown in the figure below, the interface shows that the laser is working in external control simulation, the AD mode is off, the red light is on, and the laser is outputting. The laser output power is 19,800 watts; the power-on time is 10 hours and 41 minutes today, and the laser output time is 8:33 minutes today. The operation is normal.

When to go online

Today, we introduced you to the general situation of Raycus Cloud Platform. In fact, we have more practical functions, such as the monitoring of the laser body itself (non-parameters) (for example: the temperature and humidity inside the chassis, the operation status of the on-board air conditioner, etc.), and the monitoring of the external auxiliary equipment of the laser (for example: water cooler, etc.) ), these are related to whether your laser can run more stably. We will introduce in detail later.

So, when will the Raycus cloud platform go online? In fact, some models of lasers have already been implemented on the cloud platform. At the same time, more functions are constantly being improved and added, such as the rich laser processing process parameters built in the cloud server, allowing customers to have more diverse choices and more precise positioning in the application process.

Raycus Laser, leading domestic fiber lasers into the "cloud era"!