Lithium-ion batteries have the advantages of high specific energy, long cycle life, small self-discharge, no memory effect and no pollution, and are widely used in various electronic devices and vehicles.

From the manufacture of lithium battery cells to the formation of battery packs, multiple welding processes are an important part of the battery manufacturing process, which will directly affect the cost, quality, safety and consistency of the battery.

However, conventional fiber lasers are often used in the welding process of lithium battery production, which has the problems of unstable welding process, spatter, pores, rough appearance of the weld, poor consistency and high-grade aluminum weld cracks. Raycus RFL-ABP series of beam adjustable fiber lasers show sufficient advantages in welding quality and welding efficiency, which can perfectly solve the above problems.

The beam adjustable fiber lasers is a two-in-one beam composed of a central beam with a small spot and high energy density and a larger ring beam. Compared with other lasers (gas, solid, semiconductor, conventional fiber lasers), beam tunable fiber lasers have the following welding advantages:

● The power of the center/circular spot can be adjusted independently to achieve high-quality, high-speed and uniform welding;

● Less welding spatter, almost no spatter;

●Reduce the welding seam porosity and crack tendency;

● The keyhole is larger and more stable, the welding seam is formed stable, and the consistency is good;

● Suitable for high-speed welding of lithium battery, automobile manufacturing and general industry.

Welding application examples of

beam adjustable fiber lasers in lithium battery industry

Regarding the laser welding process of beam adjustable fiber lasers in the lithium battery industry, we use Raycus RFL-ABP series beam adjustable fiber lasers to conduct related process experiments, let’s see how the welding effect is!

Battery shell welding

The thickness of the battery shell material is usually 0.2~2mm. Such parts have strict requirements on welding spatter and the appearance of the weld seam. The main requirement is airtightness, and the welding seam strength is not high.

When conventional fiber laser welding is used, there will be air holes and blast holes that can cause sealing problems. In addition, many spatters and unstable welding process are also welding problems.

The use of Raycus beam adjustable fiber laser for battery shell sealing welding can significantly increase the welding speed, the two-in-one beam keyhole is more stable, the welding process is more stable, and the weld formation is more beautiful.

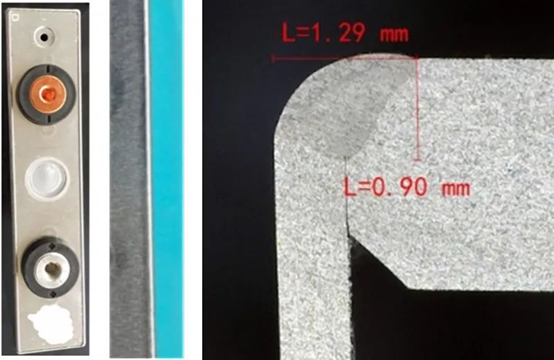

Sealing welding of square cell shell

Cylindrical battery shell sealing welding

● The welding speed of the square battery shell is as high as 350mm/s (200 mm/s is the industry standard for battery welding speed, using Raycus RFL-ABP series beam adjustable fiber laser for welding, the speed is increased by 43%);

● The welding time of cylindrical battery shell is about 0.9s/piece;

● There is almost no spatter in the welding process;

● The welding seam is formed uniformly, and there are no defects such as false welding, blast holes, cracks, and pores;

● There is no light leakage or slag leakage inside the battery;

● The tightness meets the requirements, greatly improving the product qualification rate.

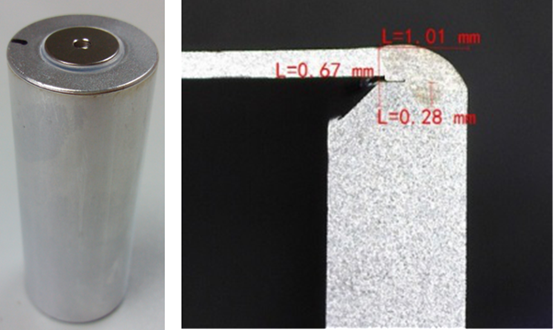

Adapter piece welding

Adapter sheet welding is an extremely important process in the production process of battery cells. It plays a role in connecting the cover plate and the cells. The quality of the weld directly affects the performance of the entire cell.

In order to ensure the overcurrent capability, the joint width of the weld joint is required to be larger. Secondly, there should be no residual spatter during welding to avoid short circuit inside the battery and affect the safety performance of the battery.

The Raycus beam adjustable fiber laser is matched with a galvanometer welding head to reasonably adjust the center power, ring power, and spiral spacing and other process parameters. It can realize circular ring welds or spiral solid round welds, effectively increasing the width of the joint surface and improving the quality of the welded joint.

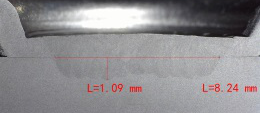

Circular weld (upper image: aluminum alloy, lower image: red copper)

● The welding speed of the adapter piece is higher than 110mm/s;

● The welded joint strength is higher than 2kN;

● The welding seam is formed uniformly and there is almost no spatter.

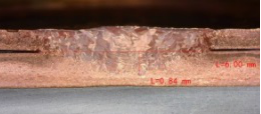

Spiral solid circle weld (left picture: aluminum alloy, right picture: copper)

● The welding seam connection width is higher than 6mm, and the connection area at the joint surface is very large;

● The weld seam is beautifully formed, without defects such as cracks.

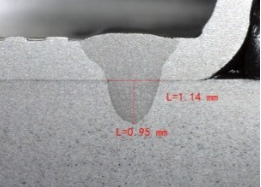

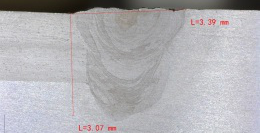

Busbar welding

The bus bar is a bridge that connects a single cell. In order to ensure sufficient over-current capability, the connection must have sufficient width and low porosity. The weld penetration depth of the bus bar is generally between 2~4mm, which requires the strength of the weld. It is relatively high, and the requirements for weld surface quality and spatter are also stricter.

Using Raycus beam adjustable fiber laser with galvanometer welding head for swing welding, by optimizing the power ratio of the center spot and the ring spot, and reasonably adjusting the swing parameters of the galvanometer, it can effectively increase the connection width of the joint surface and greatly reduce it. The pores inside the weld are optimized for weld formation.

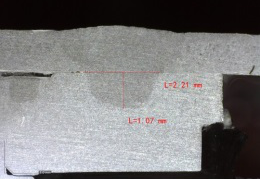

Busbar welding

● Weld connection width>2mm;

● The mechanical properties of the welded joint are excellent, and the fracture part of the tensile test is the base material of the upper plate;

● The weld seam is well formed, with very little spatter.

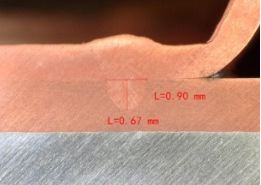

Battery module side plate welding

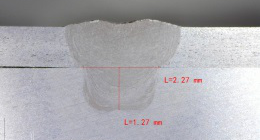

The side panels of the module are generally combined welding of 5 series aluminum alloy and 6 series aluminum alloy to ensure the strength of the outer frame. Welding cracks are a big problem in the welding of 5 series and 6 series aluminum alloys. How to ensure that the connection width is more than 2mm and obtain a "U-shaped" weld without undercuts and other defects, so as to improve the quality of welded joints is even more difficult.

Using Raycus beam adjustable fiber laser with galvanometer welding head for swing welding, through complex adjustment of process parameters, it can reduce weld pores and cracks, and improve the quality of welded joints.

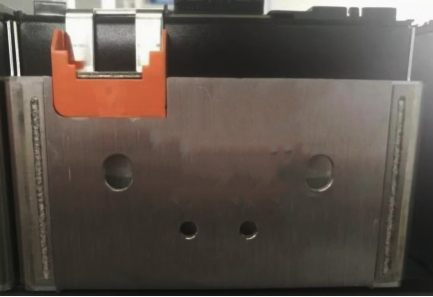

Module side plate: stacked welding head

Module side panel: butt joint

● The welding speed exceeds 80mm/s;

● The connection width of the overlapping surface of the overlap welding joint>2mm;

● The shape of the weld is close to "U" shape;

● The mechanical properties of the welded joint are excellent, and the fracture part of the tensile test is the base material of the upper plate;

● The welding seam has no defects such as cracks and undercuts, and the shape is uniform.

Judging from rigorous testing and customer field application performance, Raycus' RFL-ABP series of beam tunable lasers perform very well in lithium battery welding applications, with a speed increase of about 43%. At the same time, the welding seam is of higher quality and more beautiful, and it is bound to become a powerful model in the field of battery manufacturing and high-end welding.