The MOPA Fiber Laser is used to mark text, vector diagrams, two-dimensional codes, pictures, etc. on different materials, which are generous and beautiful, durable and wear-resistant. Deep carving is a typical application of MOPA technology.

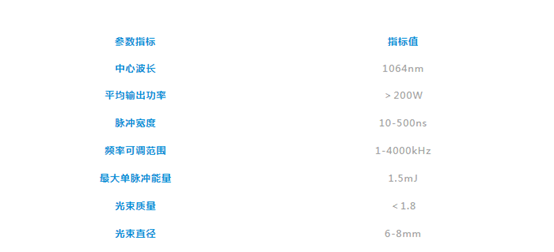

According to the different requirements of various industries for deep engraving technology, MOPA fiber lasers of different powers are used. Raycus launched a new 200W MOPA fiber laser: RFL-P200MX. In metal materials, especially carbon steel, copper and other dense materials, it has obvious advantages in deep carving efficiency.

● Pulse mode and continuous mode are optional;

● Single pulse energy is as high as 1.5mJ;

● Wide adjustable frequency range;

● Multiple pulse widths are optional;

● A wider range of process applications

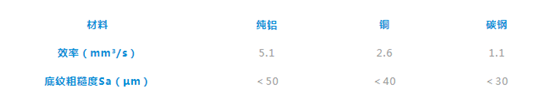

We tested the efficiency of deep engraving on the RFL-P200MX on three different materials. The test pattern area is 48mm², and the test efficiency and shading roughness are as follows:

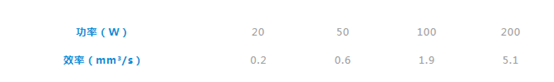

Compare the efficiency of deep carving on pure aluminum with MOPA lasers of different powers. The test pattern area is 48mm², and the test efficiency is shown in the table below:

Its deep engraving efficiency ratio is 20W:50W:100W:200W=1:3:9.5:25.5, and the RFL-P200MX deep engraving efficiency is much higher than 20-100W lasers.

RFL-P200MX deep carving 12s, depth 1.2mm

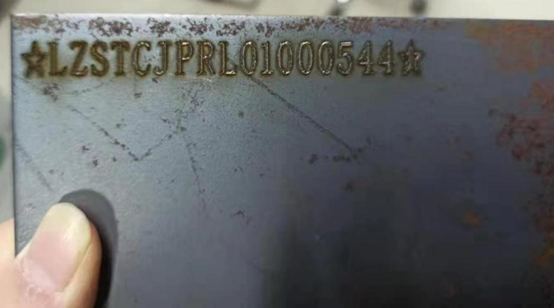

Case number one

Carbon steel frame number deep carving

Character 87mm*7.5mm, depth 0.1mm, efficiency 38s

Case two

Aluminum alloy engine body SN deep carving

20 characters, character height 8mm, depth 0.2mm, efficiency 18s

Case three

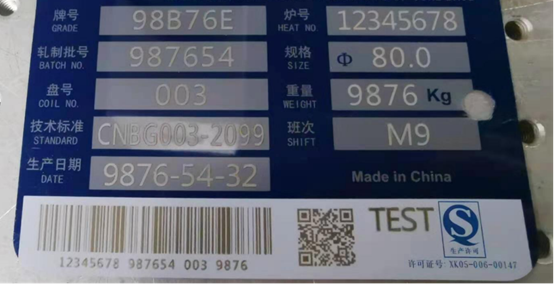

Metal nameplate information marking

Several characters, broken paint, depth <0.1mm, efficiency 16s

Case four

Carbon steel tubing marking

Marking depth> 0.2mm, marking area> 600mm²

The efficiency comparison is as follows: