The laser welding market is booming

As a modern welding technology, laser welding has deep penetration, fast speed, small deformation, low requirements for the welding environment, high power density, not affected by magnetic fields, not limited to conductive materials, and working conditions that do not require vacuum. The welding process does not produce X-rays and other advantages, and is widely used in high-end precision manufacturing fields such as automobiles, ships, and aerospace.

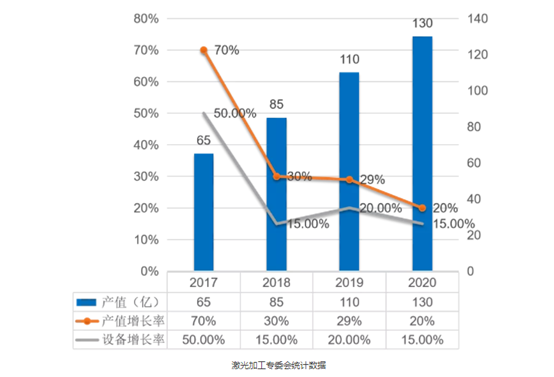

Faced with the impact of the epidemic in 2020, although the overall gross profit margin of China's laser industry has declined, the scale of the industry and industry revenue have once again shown new breakthroughs. Among them, the market size of China's laser welding equipment industry has reached 13 billion yuan, which is growing rapidly. The trend of transformation and upgrading of traditional industries is obvious, and the welding sector of non-metallic materials is growing rapidly.

Domestic substitution is the general trend

With the transformation and upgrading of my country’s manufacturing industry, the requirements of many industries for product welding quality continue to increase. Under this background, the application penetration rate of laser welding in many industries continues to rise, especially in the processing and manufacturing of metal materials and parts. Its penetration rate is at a relatively high level. Among them, the automobile industry is an important application market for laser welding in my country.

Fortunately, the high-power welding field has also begun to gradually use domestic light sources, and the growth prospects are considerable. In industries such as lithium battery manufacturing, automobile manufacturing, rail transit, and ship manufacturing, laser welding, as an important link in the manufacturing process, has also ushered in a good opportunity for development. With the continuous improvement of the performance of domestic lasers and the need for large-scale manufacturing to reduce costs, the opportunity for domestic fiber lasers to replace imports has come.

Raycus takes up the banner of the forerunner

Under the background that domestic fiber lasers are ushering in large-scale replacement of imports, Raycus actively explores high-end application fields such as laser welding, and continuously develops and customizes fiber laser products and solutions suitable for different needs. Under the influence of the epidemic in 2020, Raycus sales of laser welding lasers increased by 152% year-on-year, and a number of special welding models were launched.

Since the release of the ABP laser with adjustable beam in 2020, the market has responded well. In order to meet the needs of more application scenarios, Raycus has enriched the model ratio of ABP lasers in 2021. In the past, there was only 6+6 models. Now it has developed 6+6, 4+4, 4+2, 2+4, 3+3, 2+2 and other models. Different models can meet different application requirements. The entire series of ABP lasers use the multi-core fiber independently developed by Raycus, which can independently adjust the power of the center core and the ring core; a plasma cloud is formed during the welding process, and there is almost no spatter; the surface of the weld is smoother and flatter, also the penetration is deeper and the molten pool is wider.

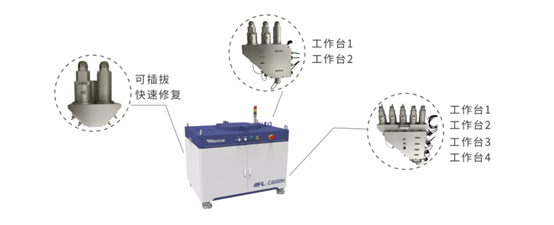

The high-power fiber laser with shutter can meet the requirement of multi-station sharing a laser, cutting and welding at the same time, saving purchase costs for enterprises;

The 100kW fiber laser is about to be delivered and will have a profound impact on aerospace, ship high-speed rail, nuclear power and other industrial fields, including high-pressure steam pipeline welding, ship high-speed rail and spacecraft and other large workpiece body welding.

At the same time, in the face of the increasingly prosperous laser hand-held welding market, Raycus launched a small-volume hand-held welding special laser, which reduces the volume and weight by about 50%, making integration easier.

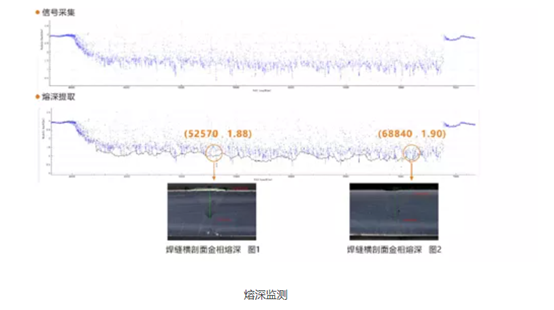

In addition, Raycus Laser also launched a welding inspection system This welding inspection system can monitor welding quality in real time before welding, during welding, and after welding, reduce enterprise inspection costs, improve production efficiency, and solve the pain point problem of high-automated enterprises that is difficult to balance between cost, efficiency and quality.

From the beginning of 2018 to the layout of welding, to the formation of a multi-model, multi-functional, multi-scenario, laser welding family including inspection systems in 2021, Raycus Laser has demonstrated its strong technical research and development strength and determination to open up the welding market. At the moment when the high-power laser cutting market is crowded together and blindly fighting for prices, to get rid of homogenous competition and open up new application markets, Raycus Laser takes the lead in high-end applications.